An Artificial Intelligence Sensor Network

Vehicles, bridges, roads, dams and buildings can all benefit from improved structural health monitoring (SHM). SHMSense is our wireless Internet-of-Things (IoT) smart sensor node system comprised of a network of sensors intelligently designed to assist in the real time assessment of structural damage. It improves the accuracy and reduces the manpower needed for structural inspections. Damage identification and maintenance intervention is possible before eventual partial or full structural failures.

As low-cost sensors have become more ubiquitous through the adoption of IoT, they are being deployed in large numbers to help with the inspection process. However, most large scale sensor-based systems employ modal analysis models that tend to over-generalize, or use accelerometers to calculate displacements that tend to drift and cause errors that could miss local structural changes over time. The net results of this inadequacy are higher inspection and repair costs, increased probability of structural failure, and potential safety hazards.

Our solution is designed to overcome these specific weaknesses:

- Sensors do not measure precise local structural defects

- Damage types are variable

- Data analysis tools are for macro rather than local defect detection

Wireless Sensor Node Network

In real-world situations, sensor placement, physical distance, power limitations, and connection problems make detection and response complicated. Our approach is a distributed model that employs a flexible integrated system of wireless cognitive sensor nodes that collect data, optionally learn patterns and store memories, and act locally on inputs. Some, but not all, calculations would occur at the back-end server, giving the system the flexibility to withstand shocks to the overall network, such as damage, disconnects or power outages, while still maintaining independent partial or complete system functionality.

Our solution is SHMSense, an intelligent wireless IoT sensor monitoring network that detects structural abnormalities and generates appropriate responses. We use a physically networked sensor node arrangement suited specifically to this type of architecture. Since our team’s areas of expertise include both wireless hardware and neural networks, we have a unique ability to connect our hardware together as smart sensor nodes. These “intelligent” nodes are independently capable of processing various input sensor data, while also being able to link to other nodes with optional assignable weights in a potentially much larger network.

Sensor Nodes

Current sensor technologies include accelerometers, strain gauges, acoustic sensors, temperature sensors, corrosion sensors, etc. These various sensors can be difficult to deploy, require many sensors and only provide measurements at the point of attachment. Our Wireless-to-Sensor Node (W2SN) solution replaces these traditional sensors in quantity and complexity, thereby reducing the deployment cost and facilitating the adoption of SHM systems.

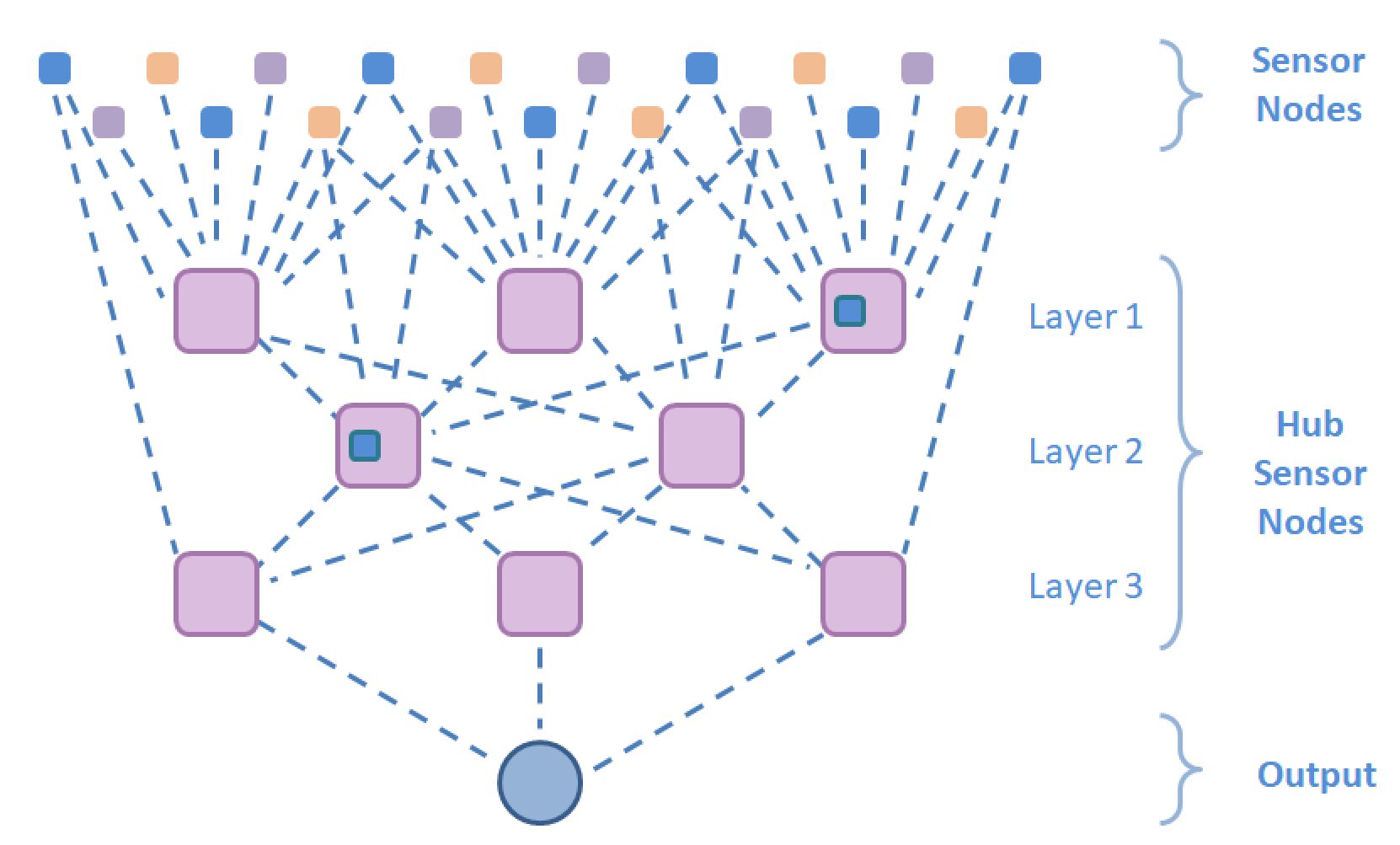

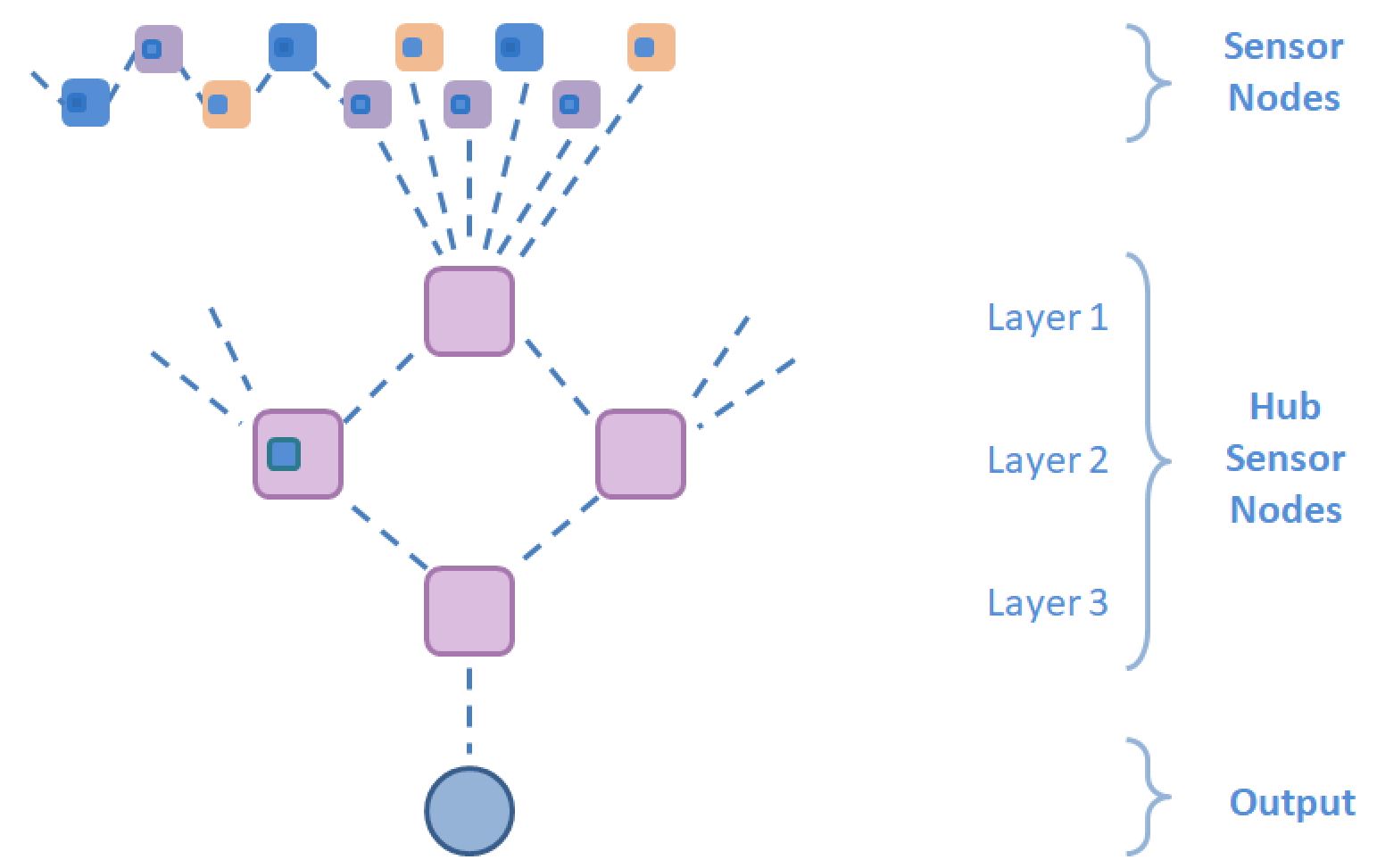

In SHMSense, the sensors themselves are distributed throughout the structure in wireless sensor nodes. Intermediary sensor nodes are called hub nodes. Although actually sharing the same hardware platform, sensor nodes typically reside at the edges of the network, whereas hub nodes are expected to connect to more than one sensor node. Sensor nodes may also be daisy-chained, such as along a tunnel or wing. They may also connect to more than one hub, and the hubs themselves may connect to other hubs in a mesh network topology.

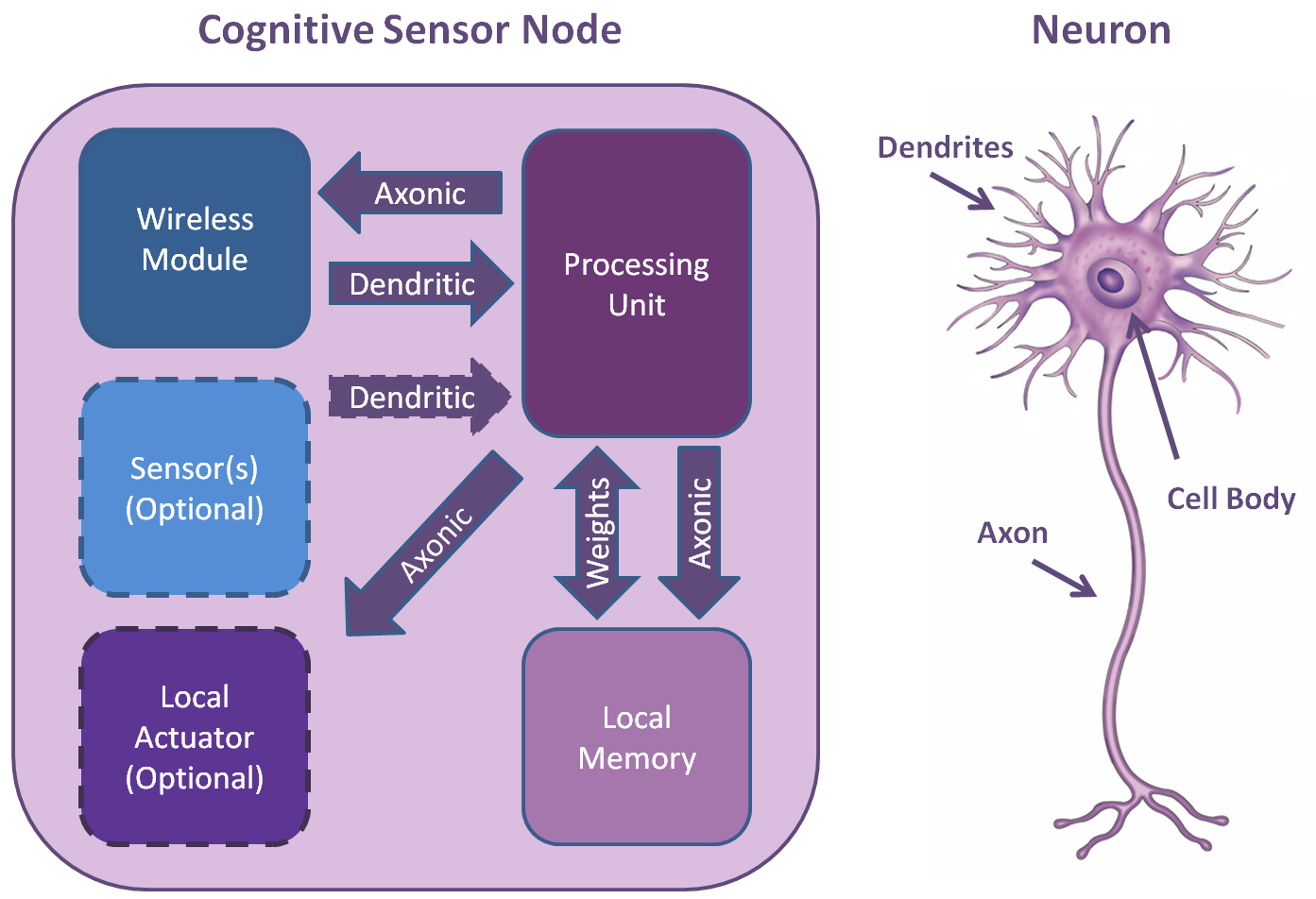

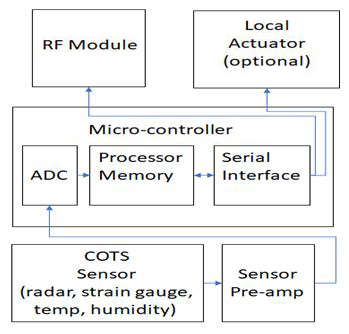

A single smart sensor node includes several components that also allow it to function as a hardware neural element. Input signals arrive as the outputs from other sensor nodes, and the internal processing unit generates a local output that may again serve as the input for other nodes. On board memory holds weights and biases of its connections and the results of any calculations. Multiple sensors can optionally be included within the node, and nodes may also house a local actuator for initiating external functions. The processing unit performs internal calculations, which may be the radar displacement algorithm, the identity function, or a full deep learning network model response with numerous hidden layers with multiple hidden units per layer. The figure below shows the proposed neuronal structure of the smart sensor node.

Software Platform

A data collection server connects to the various sensor source inputs for collection and storage of data in a database. A simple cloud-based panel interfaces with the server, accessible by a web browser, and it allows us to select and monitor sensor modules, hubs, and control the IoT responses. This scalable system will allow us to view and control the physical IoT wireless mesh network as a collective whole. The web application has panels including Operational Controls, Response Models, Sensor Node Management, Database Management, and Reporting. The Sensor Node Management panel is the one that allows for the addition or removal of different types of sensor nodes.

Sensor Node Hardware

The SHMSense sensor node hardware module is re-configurable by plugging in any sensor type (e.g. radar, strain gauge, temp, humidity, etc.) and is signal conditioned with a pre-amplifier/filter before being digitized by the integrated Analog-to-Digital Converter (ADC) in a micro-controller module. Signal processing and actuation control software is programmed into the micro-controller and data is routed to the RF module for data transmission to the rest of the intelligent network. If desired, a local actuator is also controlled by the micro-controller module over the serial interface. The block diagram is shown in the figure below.

Low-Power Operation and Energy Harvesting

In order to deploy these sensor nodes throughout a structure, it’s often preferable to use low-power systems or energy harvesting wherever possible. One prototype of our sensor node integrated with a solar panel is shown in the following figure.

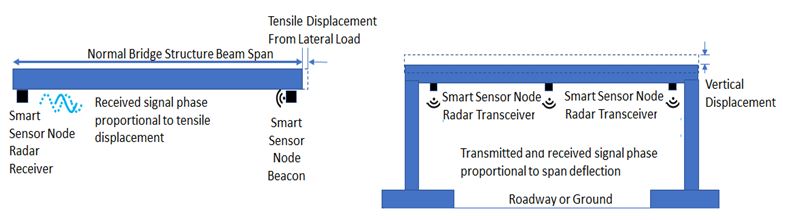

Radar Sensor

A radar sensor sub-module permits monitoring sub-millimeter deflections across large structural beams and spans. This is accomplished by measuring the phase of a beacon signal transmitter attached to the structure across the span of interest, where the phase modulation of the received signal is proportional to the physical displacement. This configuration permits the measurement of any tensile displacements along the span. In the case of vertical deflection measurements, the radar sub-module measures any phase variations from the reflected signal with the transmitter pointed from the span to a stationary point below the span (e.g. footing or road).

The measurement range can be increased with the use of a transmitter beacon rather than relying on the weaker back-scattered radar signal. The radar sensor works best in a line-of-sight configuration. Non-line-of-sight measurements make use of average phase measurement from RF diffraction and multi-path data.

The radar sensor can be used to detect hidden cracks and voids that are not visible since the 10 GHz radar can penetrate reinforced concrete to approximately 6 inches in depth. For building SHM applications, since most buildings are constructed with steel studs covered with drywall, the radar can measure reflections from the underlying structure even when visually occluded. The sensor module response is improved through the incorporation of sensor fusion of the RF sensor with an embedded Inertial Measurement Unit (IMU). This combination increases the displacement measurement precision and accuracy by eliminating the position drift issue associated with the double integration of accelerometers.

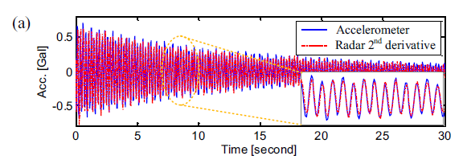

Since it can measure displacement directly, the radar sensor can also be used to obtain vibration information comparable to that obtained with an accelerometer, as shown in the figure below. This is an additional source of data that can be utilized to train the operational neural networks throughout the SHMSense network.